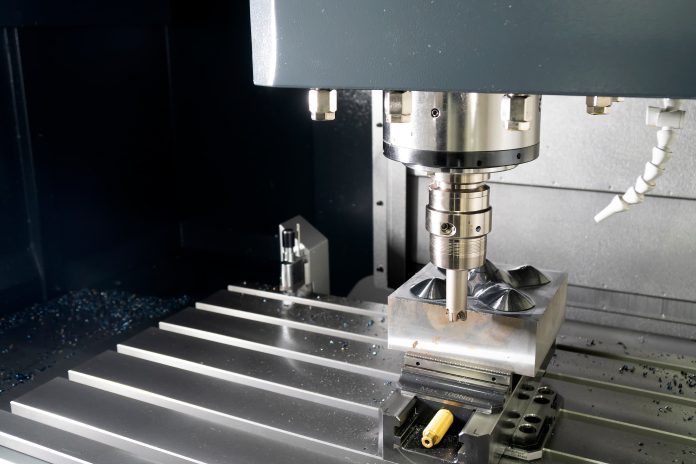

CNC turning is a popular manufacturing process that utilizes computer-controlled machinery to produce precision parts from metal or plastic. This process is ideal for businesses that require high-quality parts in low volumes, as it can be done quickly and efficiently. CNC turning is versatile and can be used to create a wide range of parts, from simple brackets to complex engine components. Additionally, CNC turning can accommodate various materials, including aluminum, brass, and stainless steel.

Choosing a reputable manufacturer with experience in your industry is essential when selecting CNC turning. This ensures that your parts meet your specific requirements and are made to the highest standards. CNC turning is a reliable manufacturing process that can produce high-quality parts quickly and efficiently.

What are various types of CNC turning?

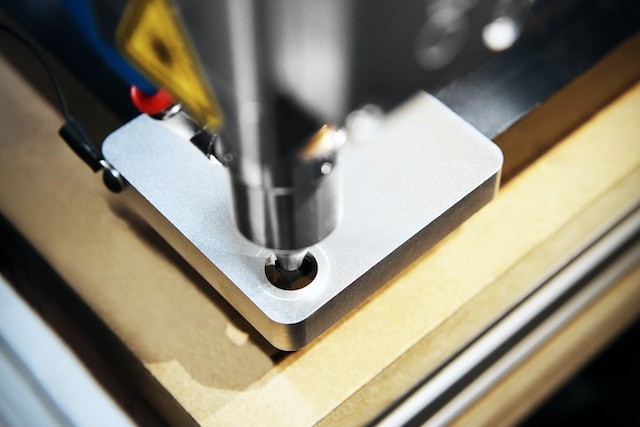

Horizontal CNC turning is the most common type, where spindles are mounted on a horizontal axis, and parts rotate around a vertical axis. It’s suitable for large parts with long diameters.

Vertical CNC turning is less common but advantageous for small parts with short diameters. Spindles are mounted on a vertical axis, and parts rotate around a horizontal axis.

Turret CNC turning uses a turret to hold cutting tools and is faster than other types of CNC turning.

Swiss-style CNC turning is more precise than other types and uses a smaller, more versatile Swiss-style machine.

Gang-style CNC turning uses multiple spindles and is faster than other types of CNC turning.

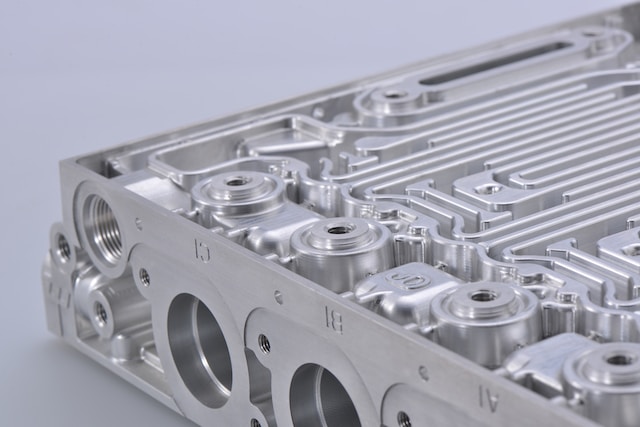

CNC turning is used in a wide range of applications, from creating small to large parts. It can produce intricate designs that would be difficult or impossible to create with other methods. CNC turned parts are used for both functional and aesthetic purposes, found in everything from engines to medical devices and decorative items like jewelry and sculptures.

What are some common applications of CNC turning?

Aerospace: CNC turning is used in the aerospace industry to create parts for aircraft engines, landing gear, and other components. These parts require high precision and durability, and CNC turning can deliver both.

Automotive: CNC turning is used in the automotive industry to create parts for engines, transmissions, brakes, and other components. CNC turning can produce high-quality parts quickly and efficiently, which is important for the fast-paced automotive industry.

Medical: CNC turning is used in the medical industry to create parts for medical devices, such as implants and surgical instruments.

Electronics: CNC turning is used in the electronics industry to create parts for electronic devices, such as connectors and housings.

Defense: CNC turning is used in the defense industry to create parts for weapons, vehicles, and other components.

Industrial machinery: CNC turning is used in the industrial machinery industry to create parts for machines, such as pumps and valves. These parts require high precision and durability, and CNC turning can deliver both.

Custom projects: CNC turning can also be used for custom projects, such as creating one-of-a-kind parts for art installations, sculptures, and other decorative items. CNC turning can create intricate designs with high precision and accuracy, making it a popular choice for custom projects.

CNC turning is a reliable and efficient manufacturing process for creating high-quality, low-volume parts. It offers precision, versatility, and accommodates a range of materials and designs. You can take advantage of the benefits of CNC turning and create parts that meet your exact specifications. To know more about CNC turning, click on the link, https://sacher-cnc.com/en/cnc-turning/